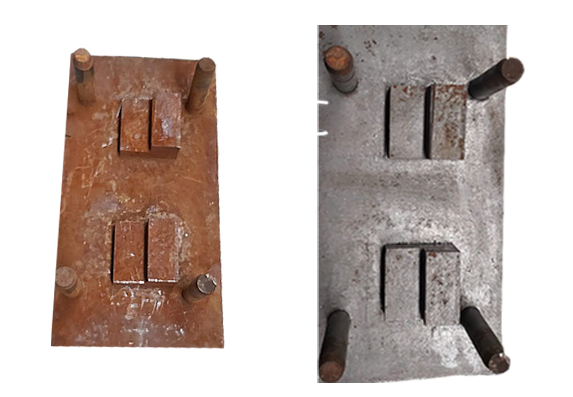

The finish durability of any metallic surface is based on the pretreatment, with a good pretreatment the piece could reach over 2000 hrs on the spray salt chamber, nonetheless there should be a work between pretreatment, the quality of the powder coating and the quality of the water in the process, in order to reach the highest quality standards.

Detergents

The detergents are a key part of any cleaning system, its main purpose is to remove any carbon, heavy or light oils, light oxides or any other scrap proper of the metal.

Outstanding formulation:

The formula of our detergents is precise to each of our clients, could be used by immersion or aspersion.

Phosphates

Light phosphates (Iron Phosphates), Coslett Phos 1500, and heavy , (Zinc , Nickel and manganese), Coslett Phos 2000, immersion and aspersion.

- Free of molybdates.

- Free of heavy metals.

Seals

Seals are a very special part of any process that wants to achieve more hours on the salt spray chamber and it also helps the process to be more stable.

- COSLETT SEAL These are non chromic seals.

- COSLETT SEAL This is a chromic seal.

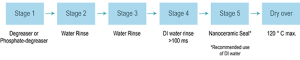

Nanotechnology

The technology is always moving and so is Chemical Coslett, giving a step forward, creating products based on nanotechnology, this kind of products have certain advantages against the conventional phosphate products, they are more eco-friendly, produce less toxic sludge, economizes the line and reduces productivity costs.

- COSLETT CERAMIC

- COSLETT CROSS FILM

This process includes a Zirconium-based nanoceramic seal.

The process can reach 1000 hours of saline chamber or more, this also depends on the quality

of the powder coating.

Additives

ADITIV is a diverse line that goes from neutralizers, additives for the PHOS line and also for the DEOXI line, etc.

- COSLETT ADITIV

Deoxidants

This line is made essentially for descaling salts provoqued by chemical cleaners, pretreatment products, or concrete mixtures.

COSLETT DEOXI